Water-methanol mixture with 05 mole fractionof each component was considered to get the maximum recovery 995 of Methanol at top. Distillation is the most well known separation technique used in the industry sector.

Optimizing Distillation For Increased Methanol Capacity

Distillation columns are used for separating crude oil into fractions to be used for transport power generation and heating.

. In this system syngas is converted to methanol as well as DME Water and gaseous by-products at steady state and uses a total of four distillation columns. 15230 m3hr Temperature of steam at 3 kgcm2 -g 14297 c Distillation time 000 hrs Pressure dropm 6746 mm Hgm Total CTW Water Req 2025 m3hr l of steam at 3kgcm²-g 50816 kcalkg Total pressure drop 80. A fixed amount of synthesis gas is fed into the system and the effects of the many design optimization variables on the yield of methanol the energy costs and the capital costs are evaluated.

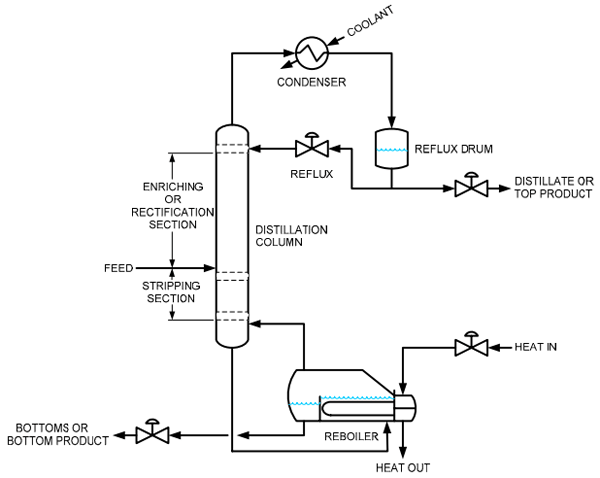

A distillation column is made up of several surfaces where each component can achieve equilibrium in the gas and liquid phase. In the Aspen Plus there is an inbuilt model known as RADFRAC which is meant for the simulation of the distillation columns. 𝐹 𝑋 𝐹 𝐷 𝑋𝐷 𝑊 𝑋𝑊 50 02 𝐷 08 𝑊 0.

A simple binary system of 50 water and 50 methanol. Distillation main principles Rhum Agricole May 11th 2018 - This page presents distillation Its The process was perfected with the use of pot stills where the liquid obtained from esters methanol and tails waterCONTINUOUS BINARY DISTILLATION D UMN EDU APRIL 19TH 2018 - 1 CONTINUOUS BINARY DISTILLATION OBJECTIVE THE OBJECTIVE OF THIS EXPERIMENT IS. Some of the purified methanol is to be used internally for the production.

Methanol water distillation chemical. During operation the system can either be switched into Maximize DME Mode or Maximize Methanol Mode. These variables include reactor pressure reactor.

This is because these two materials like each other a lot and are reluctant to separate. The methanol is recovered by separating it from water and other contaminants through distillation producing a methanol product at a minimum of 9985wt purity. Process overview for the base case design.

The two-column distillation unit represents the low-cost unit and the three column distillation unit is the low-energy system. The paper as such best describes the modeling and simulation of a distillation column using ASPEN PLUS to obtain 995 composition of methanol in. Columns currently range widely.

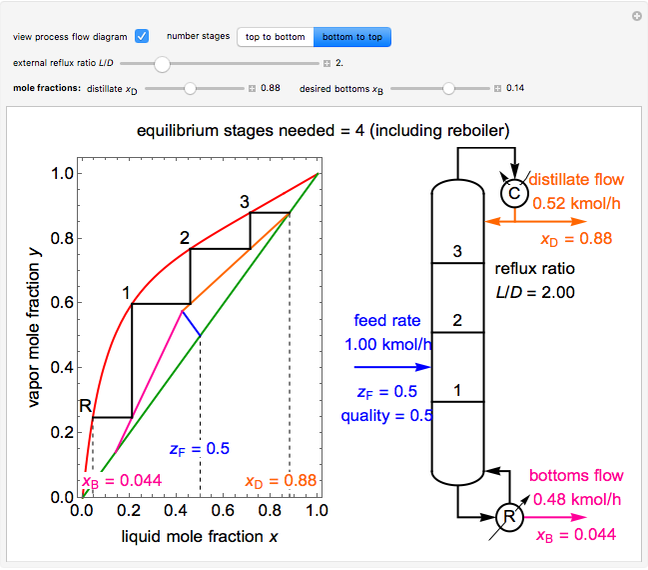

IPA-Methanol-Water 8KLday - Read online for free. Distillation Column Design 2012 Prasanna Welahetti Page 9 33 Equilibrium data of methanol and water mixture 33 Methanol Water Equilibrium Data 34 Temperature Composition Diagram of methanolwater 34 Calculation of Minimum Reflux Ratio 341 Drawing q line Feed is at saturated liquid condition. Distillation column for the separation of water-methanol mixture in this work.

A very tall distillation column is required for separating water from methanol. Distillation Column Design Methanol-Water - Free download as Word Doc doc docx PDF File pdf Text File txt or read online for free. Vapor-Liquid Equilibrium VLE It is useful for graphical design in determining the number of theoretical stages required for a distillation column.

Components in raw methanol 3. Process Simulation Maurizio Fermeglia Trieste 22 November 2021 - slide 4 RadFrac in Aspen Plus Vapor-Liquid or. The design optimization and better control of refinery processes becomes possible via dynamic simulation.

Water and methanol having different boiling points can be separated through distillation. Abayomi BCH2008001 as the group leader Obafemi Awolowo University SUBMITTED TO. This work includes three steps.

Distillation columns can be used to separate air into pure oxygen and pure nitrogen. A distillation column separates methanol from water. Therefore the aim of this report is to design a distillation column for the separation of methanol water mixture.

Distillation column design and 5. Fuel and AA grade methanol 3. Moreover the whole process is optimized to obtain the best operating parameters and suitable.

Journal of the department of chemical engineering Obafemi Awolowo University 2013Volume1 001-006 BATCH DISTILLATION OF METHANOL FROM ITS AQUEOUS SOLUTION WATER GROUP ONE MEMBER K. June 7th 2018 - design of extraction column methanol recovery system for the tame reactive distillation process the objective of this column is to separate methanol from waterexcess methanol recovery in biodiesel production process. It therefore requires a lot of heat energy heavy boiling to achieve the required.

Methanol 646 Ethanol 784 156 Methanol 646 iso-Propanol 823 226 Chloroform 612 Acetic acid 1181 615 516. Therefore according to q line equation q value. In this article a methanol distillation unit consisting of three columns has been.

Pure water has a boiling point of 100 0C and pure methanol has a boiling point of 65 C. The design of the methanol distillation unit primarily depends on the energy situation in the front end. Prasanna Welahetti Page 7 Distillation Column Design 2012 There is no any chemical reaction inside the column 32 Mass balance Overall Material balance around the envelope shown.

DISTILLATIONABSORPTION COLUMN DESIGN ChE 4253 - Design I 1800 or earlier Now. The factors that affect distillation column operation Lets clarify some of the termonology that is used in distillation by considering a two component mixture eg. MR SANDA Department of Chemical Engineering Date submitted.

First to develop a code in MATLAB v76 to apply to the mathematical model of the column. 𝐹 𝐷𝑊 50 𝐷 𝑊 Material balance for MVC around the envelope shown. Columns are used to distilling water in order to remove impurities.

A typical equilibrium curve for a binary mixture. Besides a detailed solution is given to separate the azeotropic waterbutanol solution which is formed during the process. The second step is to simulate the column using HYSIS.

The main reactive distillation column and a downstream unit to purify methanol product and recover excess raw materials. Enter the minimum input required for the RadFrac fractional model Implement Design Specification Introduce column efficiency and hydraulic calculations. Diverted to the new methanol purification system designed and supplied by AH.

Is required to obtain high overall conversion. The water which boils at a higher temperature is separated from product methanol. Up to 10 cash back In this paper the enthalpy-concentration method was applied in order to model a steady-state continuous methanolwater mixture distillation column.

150312 Design of water IPA Column Designed by. The goal of the distillation process is to separate components from each other using differences in their volatilitiesin this case water and methanol. Binary Methanol water distillation.

A Process Integration Approach To The Design Of The Two And Three Column Methanol Distillation Schemes Sciencedirect

Optimization Of The Reflux Ratio For Methanol Water Stage Distillation Column Springerlink

Frontiers The Optimal Design Of A Distillation System For The Flexible Polygeneration Of Dimethyl Ether And Methanol Under Uncertainty Energy Research

Pdf Design And Control Of Extractive Distillation For The Separation Of Methyl Acetate Methanol Water

Separation Of Propylene Oxide Methanol Water Mixture Via Enhanced Extractive Distillation Design And Control Sciencedirect

Pdf Enhanced Methanol Recovery And Glycerol Separation In Biodiesel Production Dwc Makes It Happen

Mccabe Thiele Method For Methanol Water Separation Wolfram Demonstrations Project

The Methanol Water Distillation Column Download Scientific Diagram

0 comments

Post a Comment